Our services are designed to reduce carbon emissions and boot efficiency through precise audits conducted by highly qualified professionals

Tailored for specific industries, ensuring optimal energy savings and sustainability

Comprehensive documentation to track progress and achieve sustainability goals

Adherence to the highest standards, guranteeing compliance and operational efficiency

Get a 360 view of your energy performance across HVAC, lighting, pumps, and more.

Know exactly where you're losing energy and how much you can save

Align your facility with ISO 50001, ASHRAE, and sustainability target

Drives decarbonization by cutting energy use and emissions through data-led solutions

Improve reliability, and reduce downtime with detailed audit insights.

Back every CapEx or OpEx decision with real data and projected ROI

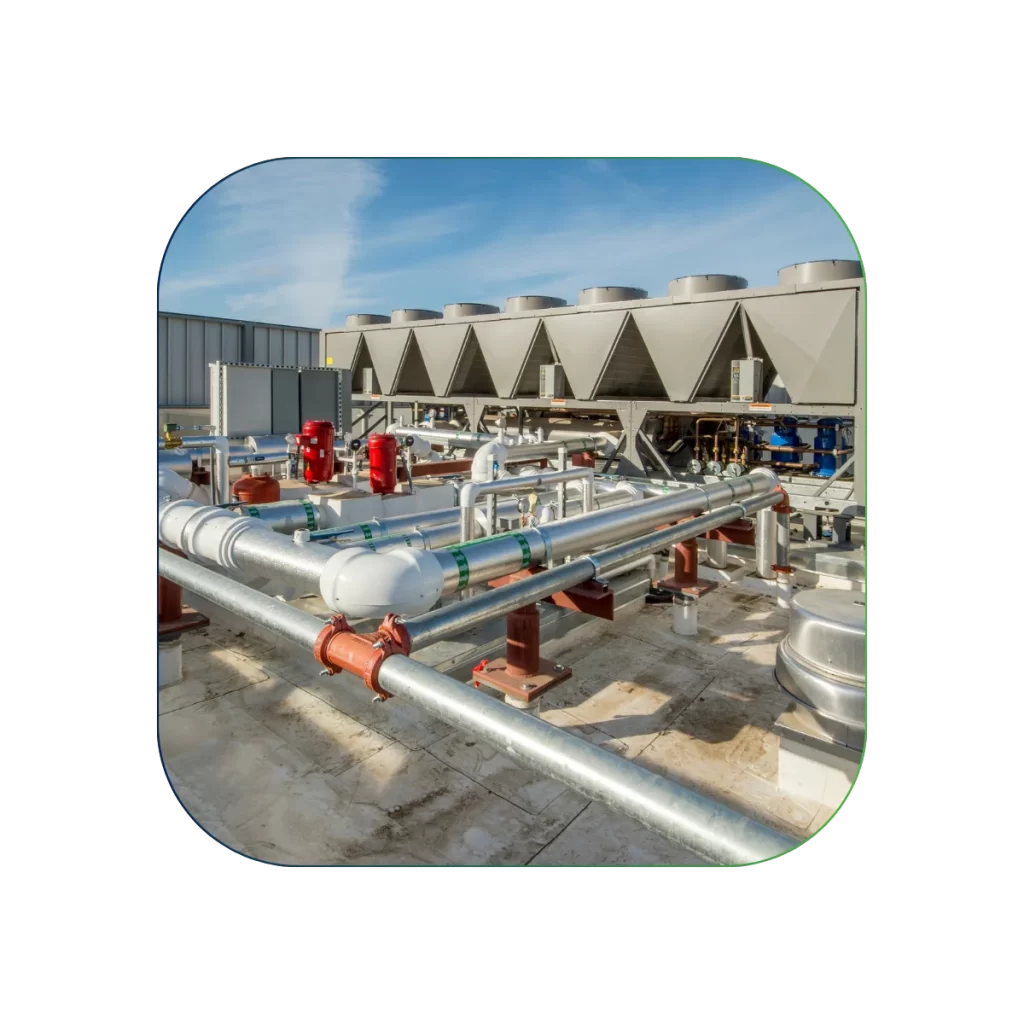

We conduct in-depth diagnostics of all critical energy-consuming equipment such as chillers, compressors, boilers, pumps, conveyors and more to identify inefficiencies

Each asset is analyzed using metric like COP, delta-T, kW/TR,and run-hour efficiency

Existing data and logic are reviewed to trace performance issues to specific faults or misalignments

Clear, actionable step are suggested to enhance performance, extend lifespan, and reduce load mismatches

Compressed air systems often suffer from hidden leaks, causing significant energy loss. We specialize in identifying, quantifying and mapping those leaks for corrective action

We use ultrasonic detectors and flow tools to scan the air network and tag leak points

Each Leak's airflow loss and associated energy cost are calculated and categorized

Recommendations include repair priorities and preventive actions for long-term savings

We analyze chiller behavior across different loads and weather conditions to identify energy wastage and reliability issues

Parameters like chilled/ condensed water temperature, delta-T, and sequencing logic are tracked and correlated with demand

Recommendation include sequencing changes, setpoint resets, and alert configuration for early fault detection

Performance is benchmarked using kW/TR and EER against industry baselines

We evaluate steam systems to enhance combustion performance, reduce fuel consumption, and minimize distribution losses

Flue gas analysis, steam trap surveys, and heat loss inspections are conducted

Combustion tuning and control schemes for part-load and startup behavior are reviewed

Proposals include condensate recovery, insulation fixes, and burner efficiency improvements

We specialize in providing ASHARE Level 1 and 2 audits that help you achieve top-tier energy performance standards

A preliminary assessment based on utility bills and basic walkthroughs to identify low-cost opportunities

Adds detailed diagnostics, load analysis, and feasibility studies for CapEx-driven improvements

Audit reports include ROI analysis and phased implementation stratergies

Audits conducted by experienced professionals to meet highest standards

Assess panels, cable routing, earthing, breaker settings, and distribution architecture

Thermographic scans detect loose connections, unbalanced loads, and insulation faults

Reports help reduce fire risks, increase uptime, and fulfill statutory audit requirements

Install high-frequency analyzers to capture harmonics, sage, swells and transients.

Analyze waveform deviations, voltage imbalances, and non-linear loads

Insights to connect poor PF, reduce utility penalties, and safeguard equipment longevity

Looking for energy efficiency solutions?